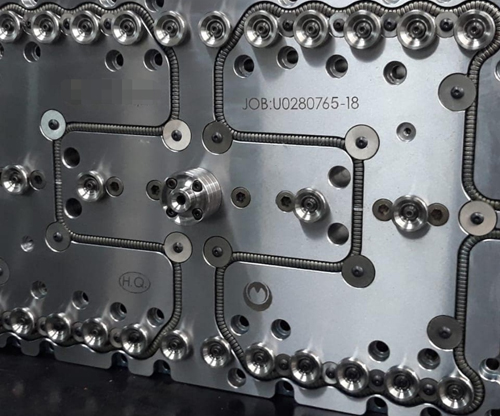

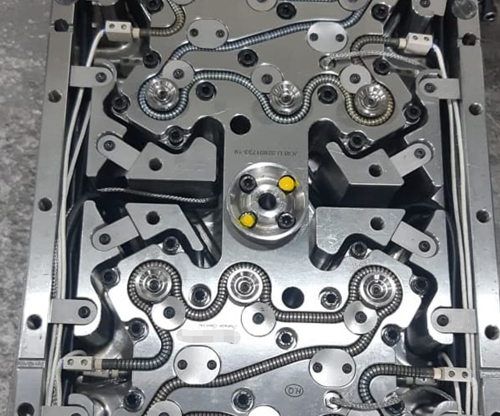

The Flexible Tubular Heaters is latest innovation for Heating Manifolds in the most efficient manner. Easiest handling, simple assembly, improved thermal performance and the simple storage are some of the crucial advantages of the Flexible Tubular Heaters over the Traditional Manifold Tubular Heating Elements. Flexible Tubular Heaters eliminates costly downtime associated with waiting for a custom bent tubular heater. Flexible Tubular Heater is your best choice for immediate, durable, high performance replacement heaters.

The Flexible Tubular heaters compress into the groove and provide excellent heat transfer. Straight lengths available Ex-Stock eliminate costly downtime associated with waiting for custom bent tubular heaters. Engineered with a robust design incorporating greater thermal mass, our Flexible Tubular Heater is user-formable with a flexible solid casing that stays in the groove, yet is easy to install.

FEATURES

- Easy installation with a uniform finish

- Can be formed by hand

- Stored in a straight condition to save storage space

- No special installation tools required

- Ground Breaking Technology ensures industry leading heat transfer

- Up to 75% sheath contact with Round and Square section heaters when recommended groove geometry is followed

- Rapid heat-up times

- Minimal temperature difference between heater sheath and heated tool

- 3-dimensional groove geometry possible

- Industry’s smallest bending radius

- flexibility enables heat to be located where it is needed; an improvement over rigid cartridge heaters

- Reduced energy costs: tool mass can be reduced.

| Sheath Material | Stainless Steel |

| Sheath Temperature Of Heating Element | Max. 700°C / 1290°F |

| Standard Connection Voltage | 230 V |

| High Voltage Test* | 1000 V AC |

| Insulation Resistance* | ≥ 5 MΩ at 500 V DC |

| Leakage Current* | < 0.5 mA at 253 V AC |

| Wattage Tolerance | ± 10% |

| Length Tolerance | ± 1.5% |