Ceramic Band Heaters were developed to meet industrial requirements for high-temperature long-lasting heaters. They are ideally suited to comply with today’s new resins, which call for ever-increasing process temperatures.

An additional advantage of the Ceramic Band Heaters is that they transfer heat through conduction and radiation. This makes their tightness on barrels less critical; thus they are less prone to thermal expansion problems.

Theoretically, there are no restrictions on the diameter that ceramic band heaters can attain; however, because these heaters utilize ceramic tiles that are available only in specific lengths, the width of these heaters falls within a certain incremental range of sizes.

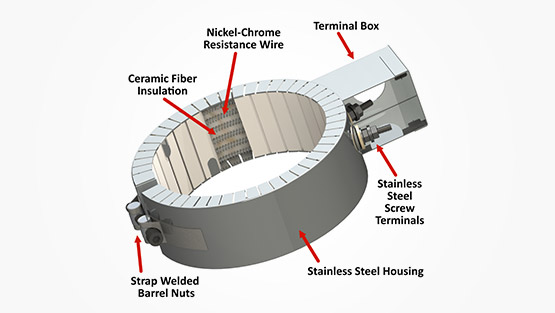

Construction

Ceramic band heaters are designed with spirally wound inner resistance coils evenly threaded through interlocking insulated ceramic “tiles”. The ceramic core or “mat” of tiles is housed beneath a stainless steel sheet with serrated edges. This combined assembly of the Ceramic Band Heater offers a flexible heating system that yields efficient transmission of conduction and radiated heat. The heat of the Ceramic Band originates from the inner coils that conduct heat at maximum temperatures. The heated coils evenly deliver heat through the ceramic tiles which radiate energy to the barrel. We offer a variety of Ceramic Band styles with customized configurations.

ADVANTAGES

- Built-in insulation minimizes the unwanted changes in temperature along the barrel

- Heat transfers through radiation, conduction, and convection, so a perfect fit is not required compared to other band heaters.

- Heat transfers are not affected by irregular surfaces or a loose fit

- Because they operate at higher watt densities, they can be used in wider increments

- The number of bands used can be reduced with simplified wiring

- The heater is safer with the cooler external surface – over other band heaters

- The flexible design allows easy installation and removal

| Resistance | +10% -5% | Overall Thickness | 15 mm |

| Wattage | +5% -10% | Minimum Dia. | 38 mm |

| Max. Watt Density | 8 watts / sq.cm | Minimum Width | 25 mm |

| Voltage | 220V AC to 480V AC | Width – Normal | Multiple of 15 + 6mm |

| Maximum Temp | 800 oC | Std. gap between edges | 5 to 10 mm |

APPLICATION

- Injection Molding Machine

- Blow Molding Machine

- Extrusion Line